The world's first 3D printed heart made of human tissue is ready for human transplantation

2019-04-25 10:26:43

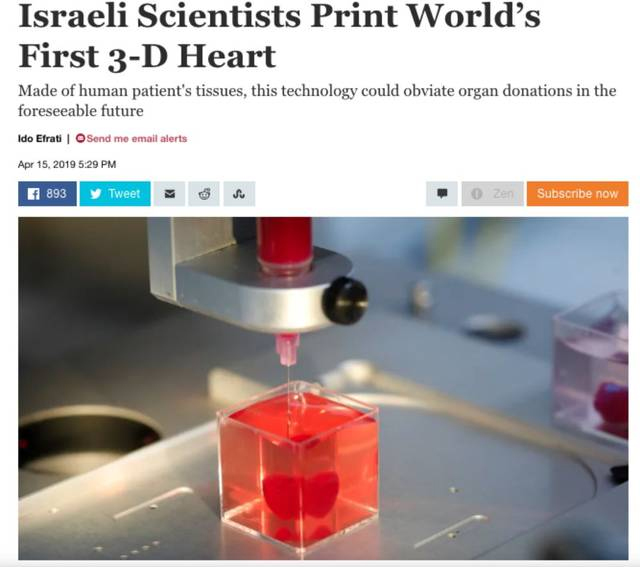

Tel Aviv University in Israel announced that it has used human tissue to 3D print the world's first complete heart, which includes cells, blood vessels, heart and ventricle. There have been 3D printed hearts before, but none of them printed blood vessels, hearts or cells.

So how is this 3D printed heart made?

It is understood that the researchers first extracted cell tissue from the human body, edited it to make it into stem cells, and then converted it into cardiomyocytes and endothelial cells, while the extracted non-cellular tissue was transformed into a "personal gel" to act as printing "ink". These materials composed of sugar and protein can be used for 3D printing of complex tissue models. The heart is only 2.5 cm long, the size of a rabbit's heart, and it cannot pump blood at present, but can only contract. The next step is to continue to cultivate the heart in the laboratory to improve its pumping function, and then try to transplant it into animals.

Tal Dvir, the lead author of the study and a professor at the School of Molecular Cell Biology and Biotechnology at Tel Aviv University, said: "In the past, people have successfully 3D printed hearts, but they did not use biomaterials, nor did they print cells or blood vessels. At this stage, although our 3D printed hearts are only about the size of a rabbit's heart, our research confirms the potential of this method in the future engineering of personalized tissue and organ replacement. The biocompatibility of engineered materials is critical to eliminating the risk of transplant rejection, which will jeopardize the treatment of heart transplant surgery. Ideally, this biomaterial should have the same characteristics as the patient's own tissue in terms of biochemistry and other aspects."

Tal Dvir also pointed out: "We must further explore the technology of printing hearts. Cells need to develop a pumping ability. They can now contract, but we need them to work together. We hope that we can succeed and prove that our method is effective and practical. Perhaps in 10 years, the most advanced hospitals in the world will be equipped with organ printers and complete the printing process as a routine." This means that 3D printed organ transplants can replace allogeneic organ transplants in the next decade.

"Organ transplant patients often need to receive immunosuppressant treatment, which may endanger the patient's health, but if the patient uses his own biological tissue as the "raw material", this problem can be solved." Patients will no longer have to wait or take drugs to prevent rejection. Instead, this technology can print the organs needed by the patient and can be tailored to the patient. "Tal Dvir added.

In the future, in addition to solving the rejection reaction, this technology can also greatly help patients with heart failure to overcome difficulties. In the past, due to the lack of donors, heart transplantation has always been a problem. Now 3D printing technology may open up a new path in the medical field and pave the way for future organ and tissue transplantation.

However, it should also be pointed out that due to the accuracy of the 3D printer, the research team cannot currently print all the blood vessels on the heart.

In fact, before the research of Tel Aviv University, 3D printing technology has been used in the medical field many times, but it is basically based on printing bones, tissues or models.

In 2014, Jingxi Hospital in Xi'an, China, used 3D printing technology to print skulls and helped a farmer with a half-skull injury and depression to rebuild half of his skull. In the same year, a research team from Peking University used 3D printing technology to make a spine and successfully implanted it into a 12-year-old boy, which was the first case in the world.

In 2015, a team from the University of Tsukuba in Japan announced that it had developed a three-dimensional liver model that can be made at a low cost using a 3D printer to clearly see the internal structure such as blood vessels. However, these visceral organ models are mainly used for research and have not been popularized in clinical practice due to their high prices.

In 2018, scientists from the Research Council Regenerative Medicine Center at the University of Edinburgh combined stem cell technology with 3D printing technology to successfully cultivate human 3D liver tissue and showed therapeutic potential at the mouse level.

This study, published in Archives of In a study published in the journal "Toxicology", scientists collected human embryonic stem cells and induced them to form pluripotent stem cells (adult cells that have been induced to become stem cells), which were then induced to form hepatocytes through directed induction. The scientists used a polymer suitable for the human body, made it into microscopic fibers, and then the fiber mesh formed a one-centimeter-square, millimeter-thick scaffold. The cultured hepatocytes derived from embryonic stem cells were then loaded onto the scaffold and implanted under the skin of mice. The results showed that blood vessels were able to grow successfully on the scaffold. In addition, the authors also found that the blood of mice contained human liver proteins, indicating that the tissue had been successfully integrated with the circulatory system and the scaffold was not rejected by the animal's immune system.

In addition, researchers at the University of Minnesota in the United States recently published a research paper in the online version of the journal "Advanced Functional Materials" stating that they have developed a new multicellular neural tissue engineering method to use 3D printing equipment to produce a bioengineered spinal cord. Researchers say that this technology may one day help patients who have suffered long-term spinal cord injuries recover certain functions.

This method effectively combines advanced cell bioengineering technology with unique 3D printing technology. It uses a biological 3D printing device, a biocompatible guide made of silicone as a scaffold, and an extrusion method to accurately print induced pluripotent stem cell (iPSC)-derived spinal cord neuron progenitor cells (sNPCs) and oligodendrocyte progenitor cells (OPCs) layer by layer into the scaffold to form a bioengineered spinal cord. 3D-printed sNPCs can differentiate and extend axons in the microscaffold channels to form neuronal networks. Calcium flux studies have confirmed that these neuronal networks are active.